Engine replacement and 5 speed gearbox conversion.

I have been running my 3 litre with a Ford V 6 engine with a 5 speed gearbox for four years due to the original engine failing and not having the funds to repair it. In 2011 I reached retirement and had a lump sum from my employer and it would be just enough to pay for the engine repair and convert to a 5 speed gearbox. I contacted a few restorers and found that their costs varied so much. I soon discovered that some would only do the engine restoration if they had the car and all of the work required. Now, I feel that i am capable of removing and replacing the engine and also doing any other work needed on the car. Some said that they had their reputation to consider and would not trust me. Now, I am the customer and paying the bill so surely I can decide what is done on my vehicle.

I found a restorer fairly local to me and I contacted them and told them that the engine was out and partially stripped. The proprietor said that if I could strip it totally and take it to him he would have a look at it and then give me a quotation. So I stripped the engine down and loaded it onto my trailer and took it to him. It needed new pistons and liners and oil pump and drive gears but the crankshaft was in excellent condition. Eventually I had a quote which I accepted and paid a deposit in October 2011. At the same time I was investigating what 5 speed gearbox would fit. The David Brown gearbox is very short due to the cruciform chassis. I found out that there is a Tremac short tail T5 available for E-Types. I compared the dimensions and the T 5 was only a few millimetres longer so I ordered one. The company repairing the engine agreed to do the necessary modification to fit the gearbox. This included an adaptor plate to fit the gearbox to the bell housing, a hydraulic slave unit that fits on the nose of the gearbox and a special clutch plate to suit. The spigot needed a bush to fit the bearing as the T 5 had a 17mm spigot and the DB had a ¾” spigot. I would have to fit a hydraulic master cylinder in place of the mechanical mechanism.

Engine on return from repair.

The gearbox fitted along with refurbished carburettors and Powerlite starter.

Engine in position ready for installation.

Engine hoisted up ready for the car to be moved forward.

Engine being lowered in position carefully.

Engine finally in place.

Tremec T5 & DB gearboxes, they are very similar in size.

T5 is a little bulkier and offset at the rear.

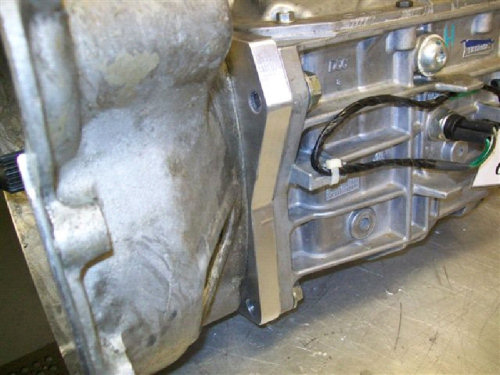

The adapter plate mating the gearbox to the bell housing.

The new gear lever position is about 30mm further forward.

A new tunnel cover fabricated from aluminium.

A new rubber gaiter fitted.

The existing cover fitted without modification.

A new clutch master cylinder. A hole cut in the floor allows access to the reservoir.

New gearbox mount fits in the existing holes and master cylinder in position.

The connection to the slave unit is by flexible hose, it was a stock item and a

little long so is coiled around.

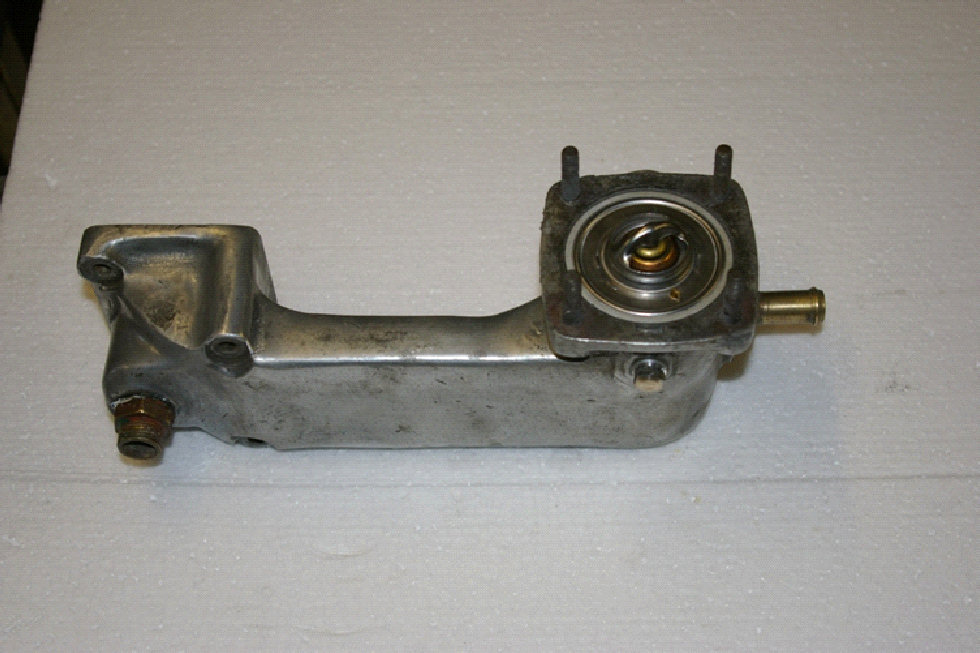

Other work I carried out was to fit a thermostat adapter to allow the by-pass to shut when correct operating temperature is achieved.

Thermostat adapter and new thermostat.

Adapter fitted in the housing.

Thermostat and adapter fitted in the housing.

Re-cored and uprated radiator, a new filler neck and later cap fitted.

With the engine in place and all pipes etc fitted and coolant in place and the engine and gearbox oil added it was now a wait for Mike Dowd who rebuilt the engine to arrive and start it. I had also fitted a disposable oil filter canister conversion.

Mike advised that I remove the plugs and prove the oil pressure before he came. When trying this I spotted oil pouring out of the oil filter. The rubber ring had blown out and it appeared that oil could not flow through the filter due to the non return valve being incompatible. So the original unit was quickly fitted with a new element and the oil pressure came up immediately and there were no leaks from the filter. The people who supplied the unit gave me a filter part number to solve the problem and that will be fitted when the next oil change is due.

Mike arrived and carried out a few checks and told me to ‘try it’. The engine fired straight away and ticked over. Then the timing was adjusted for a good tick over. However, at a higher speed there was a slight misfire. I refitted the original plug leads and caps that I had put on just before the engine failed. After a few checks, I found two faulty plug caps and the electronic ignition had a phasing problem although this was fine years ago and it had only done a few miles. A few phone calls and more checks showed that the ignition unit was correct for the type of distributor but there were two types one clockwise and one anticlockwise and my unit was the wrong one. At 2000 revs it would go out of phase and cause the misfire. A set of points and HT leads were fitted and then the engine ran okay.

The carburettors needed a tune and so a visit to an engine tuner with a rolling road was arranged. The needle was set up fine and the mixture and a balance check were carried out. I now need to run the engine in and hopefully have many miles of pleasure with the car.

Robin Allum

Here is a gallery of pictures showing the engine and gearbox renovation, and some pictures of the car as it looks now. Click on the pictures to enlarge them: